A tight weather sealed WiFi AP housing or surveillance camera used outdoors is a good example.

#Cable strain relief connector home depot Patch#

IDC or Insulation Displacement Contact terminals are what is found inside keystone jacks, patch panels, and field termination plugs.įor more information on why self-installed RJ45 8P8C connectors should be far down your list of preferential termination options see Choosing the Right Termination - Keystone Jack vs RJ45 Connector vs Field Termination Plug.īy now you are probably asking why trueCABLE even sells RJ45 8P8C connector plugs given the potential associated issues when using them on solid copper bulk Ethernet cable. Solid copper Ethernet is much better with IDC style terminations and has other key advantages. You can get more “bite” into stranded copper conductors vs solid copper conductors when terminating cable using to RJ45 connectors. Stranded copper conductors are far superior to construct Ethernet patch cables and get a durable and reusable cable (The very definition of a patch cable is something designed to be durable and flexible with male connectors on both ends). RJ45 8P8C connector plugs are the least performant and least desirable way to terminate solid copper Ethernet cable, and quite frankly if you do decide to terminate your bulk Ethernet cable with them you need all the help you can get! The strain relief boot helps take the pressure off of your termination (specifically the golden contacts) and gives it a degree of durability. Of those three reasons, the first is the most important. Helps to keep your Ethernet cables within the specified bend radius.Electrical performance stabilization since the cable cannot shift around as readily at the rear of the RJ45 8P8C connector with a boot attached.

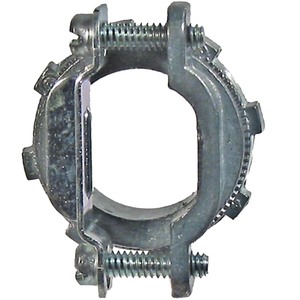

We do recommend using strain relief boots for three key reasons: Cable boots are not associated with patch panels or keystone jacks as those types of terminations typically have their own method of providing strain relief. The primary purpose of cable boots is to provide strain relief to ease pressure on the male connector plug termination. It should be noted that cable boots are only seen in the context of male connector plugs (AKA RJ45 connectors, but sometimes with field termination plugs too). There is no significant functionality difference between these strategies. Other cable boots are not molded in, but instead are slid on and locked on the cable at the rear of the RJ45 8P8C connector during the termination process. Typically, these boots are molded right into the cable jacket plastic and cannot be removed even if you wanted to take them off. In other connectors, the strain relief can be in the form of metallic connectors and grips, some of them made of metal that are crimped over the cable to provide tensile strength.Most, but not all, factory premade Ethernet patch cords come with cable boots already installed. In the case of network cables, the strain relief is called the “boot,” which is fitted over the connector after attaching the cable and the RJ-45 connector. On other cables, especially those that are manufactured separate from their connectors, strain relief often comes in the form of a separate device that is installed over the connector and the cable joint. The usual design found in consumer-grade cables is often the overmolded strain relief, which is already part of the connector itself, and looks like a segmented sleeve over the portion of the cable attached to the connector. It is an essential feature for the mechanical and electrical integrity and overall performance of all types of electrical cables. The strain relief, as the name suggests, relieves a cable of stresses and tensions that could break the conductor inside or the connection between the plug or connector and the cable.

0 kommentar(er)

0 kommentar(er)